Facts About Roar Solutions Uncovered

Facts About Roar Solutions Uncovered

Blog Article

Top Guidelines Of Roar Solutions

Table of ContentsThe Best Strategy To Use For Roar SolutionsThe Best Strategy To Use For Roar SolutionsSee This Report about Roar SolutionsExamine This Report about Roar Solutions

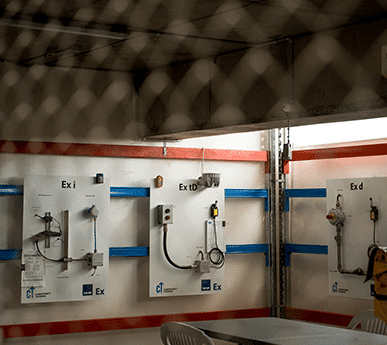

The tools register is a thorough database of equipment documents that consists of a minimum set of areas to identify each product's place, technical criteria, Ex classification, age, and environmental data. This information is vital for monitoring and handling the devices properly within hazardous locations. In contrast, for regular or RBI tasting assessments, the quality will be a mix of Detailed and Close inspections. The ratio of In-depth to Close inspections will certainly be established by the Devices Danger, which is evaluated based on ignition threat (the likelihood of a source of ignition versus the possibility of a combustible ambience )and the dangerous area category( Zone 0, 1, or 2). This variant will certainly likewise affect the resourcing demands for work preparation. As soon as Great deals are specified, you can create tasting strategies based on the sample size of each Lot, which describes the variety of random devices things to be evaluated. To figure out the called for sample size, two elements need to be reviewed: the dimension of the Lot and the category of examination, which indicates the level of effort that must be applied( lowered, regular, or enhanced )to the examination of the Whole lot. By integrating the classification of examination with the Great deal size, you can then establish the proper denial criteria for an example, implying the allowed number of malfunctioning things discovered within that sample. For more details on this procedure, please refer to the Energy Institute Guidelines. The IEC 60079 typical suggests that the maximum period between examinations need to not surpass three years. EEHA assessments will likewise be performed beyond RBI projects as part of arranged maintenance and equipment overhauls or repair services. These evaluations can be attributed toward the RBI sample sizes within the impacted Great deals. EEHA evaluations are conducted to identify mistakes in electrical devices. A heavy racking up system is crucial, as a single piece of devices may have numerous mistakes, each with differing degrees of ignition threat. If the mixed rating of both evaluations is less than twice the mistake rating, the Lot is regarded appropriate. If the Whole lot is still thought about inappropriate, it must go through a full assessment or validation, which might cause more stringent assessment methods. Accepted Whole lot: The reasons for any mistakes are determined. If a common failure setting is located, additional equipment might require maintenance. Faults are categorized by severity( Safety and security, Integrity, Home cleaning ), ensuring that immediate concerns are examined and resolved immediately to alleviate any type of influence on safety or procedures. The EEHA database ought to track and record the lifecycle of faults together with the corrective actions taken. Applying a durable Risk-Based Examination( RBI )approach is important for guaranteeing conformity and safety and security in managing Electrical Devices in Hazardous Locations( EEHA). Automated Mistake Scoring and Lifecycle Administration: Effortlessly manage faults and track their lifecycle to boost examination accuracy. The intro of this assistance for risk-based inspection even more enhances Inspectivity's position as a best-in-class service for governing compliance, along with for any type of asset-centric evaluation usage instance. If you are interested in learning a lot more, we invite you to request a demonstration and uncover how our remedy can transform your EEHA administration procedures.

With over one decade of mixed Ex-spouse experience (IECEx/ATEX, EEHA), Saipex began to promote the importance of skills of all employees included in the Hazardous Location area in 2019. In 2021, our partnership with IndEx and Tech Ability International (TSI) noted a landmark in the Saipex roadway to continue Ex-spouse improvement.

An Unbiased View of Roar Solutions

In terms of eruptive threat, a hazardous location is a setting in which an explosive environment is present (or might be anticipated to be present) in amounts that call for special precautions for the construction, setup and use tools. In this post we check out the difficulties dealt with in the workplace, the risk control procedures, and the needed expertises to work securely.

(https://www.video-bookmark.com/bookmark/6634779/roar-solutions/)

It is an effect of contemporary life that we produce, keep or take care of a variety of gases or fluids that are deemed combustible, and a series of dusts that are considered flammable. Roar Solutions. These materials can, in specific conditions, develop eruptive atmospheres and these can have significant and unfortunate consequences. A lot of us are familiar with the fire triangular eliminate any type of one of the 3 components and the fire can not happen, yet what does this mean in the context of harmful locations? When damaging this down into its easiest terms it is essentially: a combination of a certain quantity of launch or leak of a certain material or material, blending with ambient oxygen, and the presence of a source of ignition.

This is then validated through evaluation and testing and is maintained throughout the life of the installation by utilizing the right upkeep strategies, supplemented by periodic evaluation. When all these measures are taken, they should likewise be documented. The verification dossier consists of details such as the dangerous area classification illustration, manufacturers' documentation, tools accreditation, layout illustrations and calculations, assessment records, and documents of a person's expertise and continuing expert growth (CPD), such as through ECA's eCOMS software.

Getting The Roar Solutions To Work

It is essential that students recognize and have a comprehensive understanding regarding what precisely constitutes an unsafe area. The trainee should likewise know why training is essential prior to attempting to handle work or defining tools right into a hazardous location. These locations are also referred to as identified places and are defined as areas which have a high probability of site here a surge due to the feasible existence of flammable gases, vapors, cleans and so on.

Industries which contain hazardous locations are currently demanding that electrical workers that are defining or operating in these locations should have a harmful location credentials that considers them qualified. Jobs in these markets are very fulfilling so you need to be prepared. To meet this demand for the market, across the country identified training in Certification IV in Harmful area Electrical and EEHA training on the growth of experienced professionals.

The smart Trick of Roar Solutions That Nobody is Talking About

Tech Skills Australia is a Registered Training Organization giving you with the most budget friendly and quickest method acquiring your credentials - eeha certificate. Our instructors are market certified and have numerous years of process experience. Our programs have actually aided thousands of people from company managers to day-to-day employees in getting a strong hang on this not so difficult but high risk training

The training likewise includes recognizing the unsafe locations, resources of surge and the homes of unsafe products in addition to the duties and features of all events, policies, systems, criteria and practice codes attached to harmful locations. We give instrumentation and harmful area options that remain in conformity to newest AS/NZS and international market criteria.

Report this page